In this article

- 1 I. The Evolution of Maintenance in Smart Factories

- 2 II. Understanding the Fundamentals of ML in Predictive Maintenance

- 3 Real-time Sensor Data Analysis

- 4 III. Advancements Expected by 2025

- 5 IV. Case Studies: Real-World Applications and Examples

- 6 V. Overcoming Challenges and Implementation Considerations

- 7 VI. Tools and Platforms for ML-Based Predictive Maintenance

- 8 VII. The Future of Predictive Maintenance Beyond 2025

- 9 VIII. Advice for Students, College Teams, Small Businesses, and Startups

- 10 Predictive Maintenance Implementation Roadmap

I. The Evolution of Maintenance in Smart Factories

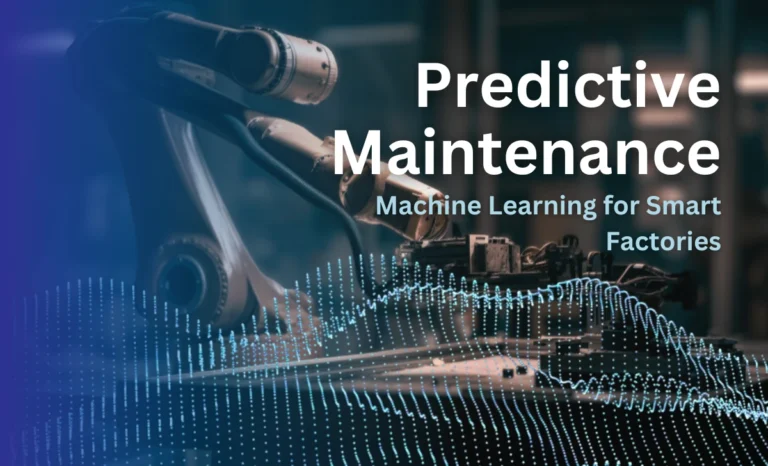

Predictive maintenance is a method that uses real-time data and machine learning algorithms to identify early signs of equipment degradation. It differs from traditional maintenance, which either fixes machines after failure or services them on a set schedule. By intervening only when data indicates a problem is developing, predictive maintenance leads to significant cost savings and improved efficiency. In addition, it can help prevent unexpected downtime and extend the lifespan of equipment.

Smart factories use sensors to collect data about critical machines, similar to measuring vital signs. ML algorithms analyze this data to identify anomalies and predict future breakdowns. Predictive maintenance reduces downtime and extends equipment lifespan. As industries move towards digital transformation, this technology is becoming essential for smaller businesses, even those previously thought of as large-scale operations. Implementing predictive maintenance can significantly improve efficiency and ultimately lead to cost savings for companies of all sizes.

II. Understanding the Fundamentals of ML in Predictive Maintenance

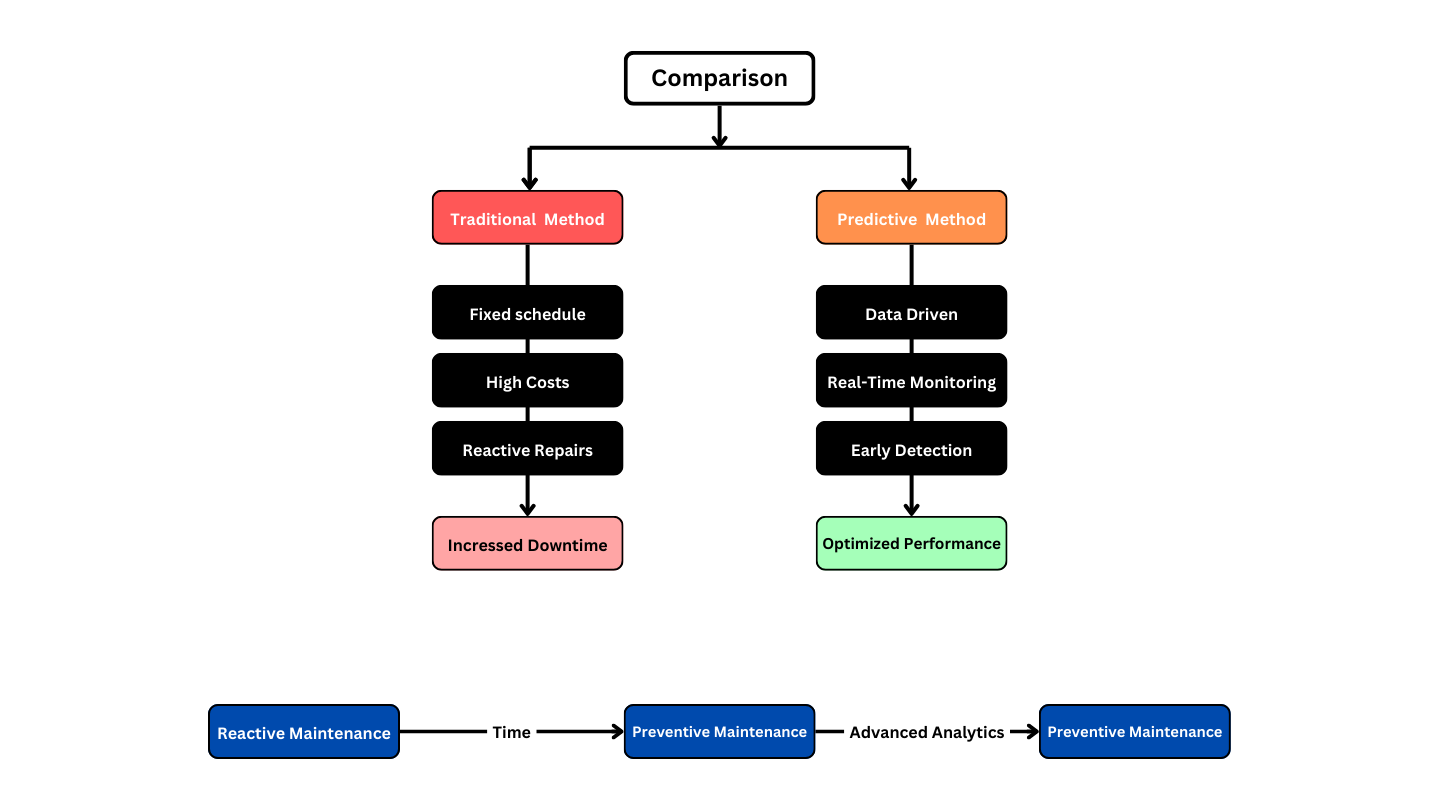

Predictive maintenance relies on machine learning, a branch of artificial intelligence that uses data analysis to predict equipment failure. ML algorithms analyze historical and real-time data, using supervised and unsupervised methods to forecast machine useful life and detect anomalies without prior examples. Machine learning allows maintenance to be more proactive and efficient. By identifying potential issues before they occur, saving time and money in the long run.

Real-time Sensor Data Analysis

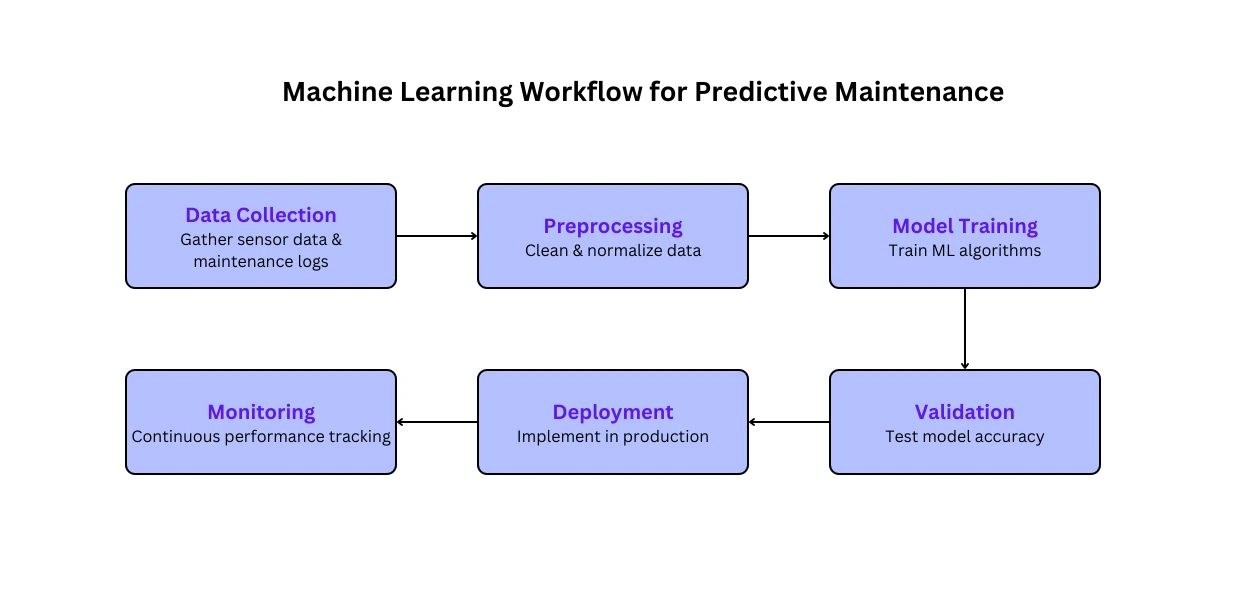

- Common machine learning (ML) algorithms predict numerical values, categorize asset conditions, and optimize maintenance schedules.

- Data is gathered from sensors on machinery and organized into time-series records and maintenance logs.

- The ML workflow includes data collection, preprocessing, model training, validation, deployment, and ongoing monitoring to ensure accurate predictions as conditions change.

III. Advancements Expected by 2025

A. Enhanced Algorithm Accuracy

- 25-30% False Alarm Reduction

- 35% Faster Fault Detection

- Transfer Learning Capability

- Advanced machine learning techniques—such as transfer learning and few-shot learning—will significantly improve predictive accuracy by reducing false positives and negatives.

- Enhanced algorithms can adapt quickly; for example, a model initially trained on CNC machine data can be repurposed to monitor similar equipment with minimal extra training.

- This rapid adaptation is expected to lower false alarms by 25–30% and improve early fault detection precision, resulting in better resource allocation and fewer unplanned maintenance events.

B. Improved Sensor Technology

- Sensor technology is evolving with wireless connectivity, IoT integration, and edge computing, enabling real-time data capture and local processing.

- These next-generation sensors provide higher resolution measurements—for instance, wireless vibration sensors now achieve 98% uptime and can transmit data with millisecond latency.

- This improved sensor performance not only simplifies installation on legacy equipment but also delivers more accurate data for downstream machine learning models.

C. AI-Driven Diagnostics

- AI-driven diagnostics will automate root cause analysis, reducing the dependency on manual interpretation and expert intervention.

- Self-learning systems can continuously update their internal models to adapt to changes in equipment behavior; for example, an integrated predictive maintenance system may reduce mean time to repair (MTTR) by up to 35%.

- These diagnostic tools leverage real-time analytics to pinpoint issues quickly, ensuring that maintenance teams receive actionable insights when they need them most.

IV. Case Studies: Real-World Applications and Examples

A. Manufacturing Plant Example

Downtime Reduction

Cost Savings

In modern manufacturing facilities, machine learning models monitor key equipment like CNC machines and robotic arms using sensors that capture vibration, temperature, and current. One plant reported that by implementing predictive models, downtime was reduced by 20%, resulting in a 15% boost in overall throughput. For instance, a vibration analysis model identified an impending bearing failure, allowing preemptive maintenance that saved approximately USD 50,000 in repair costs over a year. This led to improved operational efficiency and increased profitability for the company. The company was able to allocate those saved funds towards other areas of their business, leading to further growth and success.

B. Energy Sector Example

Energy companies are increasingly relying on predictive maintenance to manage assets such as wind turbines and solar panels. By integrating weather data with real-time performance metrics, predictive models can optimize maintenance schedules and extend equipment life by 15–20%. For example, a wind turbine monitoring system reduced unplanned outages by automatically adjusting maintenance intervals based on detected anomalies in vibration and temperature readings. The system was able to predict failures before they occurred, allowing for timely repairs and ultimately saving the company millions of dollars in downtime costs.

C. Other Relevant Industries

Beyond manufacturing and energy, industries such as automotive, aerospace, and logistics benefit from ML-driven maintenance strategies. Automotive fleets use sensor data to predict battery and engine issues, reducing unscheduled repairs by around 25%. Similarly, aerospace maintenance programs leverage predictive diagnostics to optimize inspection cycles, ensuring high safety standards while lowering operational costs. This data-driven approach allows companies to proactively address maintenance needs before they become critical failures.

V. Overcoming Challenges and Implementation Considerations

A. Data Quality and Availability

Reliable predictive maintenance depends on clean, complete, and high-frequency sensor data. Strategies such as data cleaning, normalization, and augmentation help address issues like noise and class imbalance. In practice, rigorous preprocessing has been shown to reduce model error by up to 15%, ensuring that only meaningful signals drive maintenance decisions. This ultimately leads to more accurate and reliable predictive maintenance outcomes. Ultimately leading to more efficient operations and cost savings for organizations.

B. Integration with Existing Systems

Integrating advanced predictive maintenance tools with legacy systems requires robust APIs and data exchange protocols. By interfacing with ERP and legacy monitoring systems, companies can streamline data flow and reduce integration time by as much as 40%. This seamless connectivity enables a unified dashboard that supports both new and existing maintenance workflows. This technology integration can greatly improve operational efficiency and decision-making processes.

C. Skills and Expertise

Deploying ML-based predictive maintenance necessitates a blend of domain expertise and data science proficiency. Companies must invest in training programs or hire specialized personnel—often partnering with academic institutions—to bridge technical gaps. For small businesses, outsourcing initial model development can keep costs to about 10% of the overall project budget while building internal capability over time. This strategy allows small businesses to leverage external expertise and resources without committing to large upfront costs.

D. Costs

Upfront investment, ongoing operational expenses, and hidden integration costs must be carefully evaluated against expected ROI. Studies show that successful predictive maintenance programs can reduce maintenance costs by 20–30% and achieve payback within one to two years. A detailed cost-benefit analysis ensures that every component—from sensors to cloud services—contributes to a cost-effective maintenance strategy. Ultimately, the goal is to maximize equipment uptime and optimize maintenance schedules.

VI. Tools and Platforms for ML-Based Predictive Maintenance

A. Cloud-Based Platforms

Cloud platforms like AWS IoT, Microsoft Azure, and Google Cloud offer scalable solutions for collecting, storing, and analyzing sensor data in real time. These platforms integrate with advanced ML services (e.g., AWS SageMaker or Azure Machine Learning) to deploy predictive models at scale. By leveraging cloud-based analytics, companies can reduce infrastructure costs and access global support and security features. Additionally, companies can easily scale their operations and adapt to changing business needs.

B. Open-Source Tools

Open-source libraries—such as TensorFlow, PyTorch, and scikit-learn—provide flexible, cost-effective options for developing customized predictive maintenance models. These tools support a wide range of algorithms, from regression analysis to deep neural networks, and are backed by active developer communities. For instance, a scikit-learn-based regression model can be tailored to predict remaining useful life (RUL) for specific machinery types with minimal licensing fees. Additionally, scikit-learn allows for easy integration with other data analysis tools and platforms.

C. Specialized Software

Several software solutions are designed specifically for predictive maintenance, including IBM Maximo, SAP Predictive Maintenance, and GE Predix. These specialized tools offer pre-built models, industry-specific dashboards, and seamless integration with existing operational systems. In one documented case, GE Predix reduced unplanned downtime by 25% through automated monitoring and maintenance scheduling, highlighting the value of dedicated predictive maintenance platforms. The platform also resulted in a 20% decrease in maintenance costs.

VII. The Future of Predictive Maintenance Beyond 2025

To prepare for the evolving landscape of predictive maintenance, organizations must act now to integrate emerging technologies and establish a future-ready infrastructure. Follow these steps to transform your maintenance strategy:

- Integrate Digital Twins:

Start by creating digital replicas of your most critical assets. For example, a manufacturing plant can model its primary production line machinery digitally. This twin enables you to simulate various operating scenarios and predict failures before they occur, improving planning and response. It also allows you to optimize maintenance schedules and reduce downtime. - Adopt Autonomous Maintenance:

Implement self-learning systems that automatically adjust maintenance schedules based on real-time data. For instance, leverage robotics and automated sensors to perform routine checks and minor repairs. This not only reduces labor costs but also minimizes human error in maintenance decision-making. Additionally, these systems can help identify potential issues before they become critical problems. - Embrace Advanced Connectivity (5G):

Upgrade to 5G or other high-speed networks to ensure seamless data transfer from sensors to your analysis platforms. High-speed connectivity enables near real-time monitoring and faster response times—critical when a production line halts due to unexpected equipment issues. This minimizes downtime and prevents costly delays in your operations. - Plan for Continuous Learning:

Establish a process to update your predictive models as new data arrives. Regularly review model performance and adjust parameters to reflect changes in asset conditions. This continuous improvement ensures that your system remains accurate and effective well into the future. By doing so, you can stay ahead of potential issues and optimize asset performance.

VIII. Advice for Students, College Teams, Small Businesses, and Startups

Starting a predictive maintenance program doesn’t require a huge budget—begin with the essentials and scale gradually. Use this step-by-step approach to get started:

Predictive Maintenance Implementation Roadmap

- Equipment inventory list

- Downtime cost analysis tool

- Risk assessment matrix

- Create equipment inventory

- Calculate downtime costs

- Assess failure risks

- Prioritize critical assets

- TensorFlow/PyTorch

- Online tutorials

- Public datasets

- Select appropriate tools

- Complete basic tutorials

- Practice with sample datasets

- Join online communities

- IoT sensors

- Data collection system

- Data cleaning tools

- Install sensors

- Set up data collection

- Clean historical data

- Establish baseline metrics

- Pilot plan template

- ROI calculator

- Performance metrics

- Select pilot scope

- Define success metrics

- Monitor performance

- Document results

- Network contacts

- Partnership agreements

- Knowledge sharing platform

- Identify partners

- Establish agreements

- Share knowledge

- Leverage expertise

- Scaling plan

- Model optimization tools

- Progress tracking system

- Analyze pilot results

- Refine models

- Expand asset coverage

- Monitor progress